Strengths

Wide Chemistry Expertise

INVENTYS chemistry team comprised of experienced and bright young chemists have developed a wide range of chemistry expertise that can address the challenges of diverse industries. Backed by an excellent infrastructure, strong chemical engineering and plant design expertise, this team has been able to successfully discover, develop and manufacture many processes from the laboratory to the plant scale. Our ability to safely handle many hazardous chemicals differentiates us from many of the other players in this space. An illustrative list of the diverse reactions successfully demonstrated at our manufacturing scale is listed below.

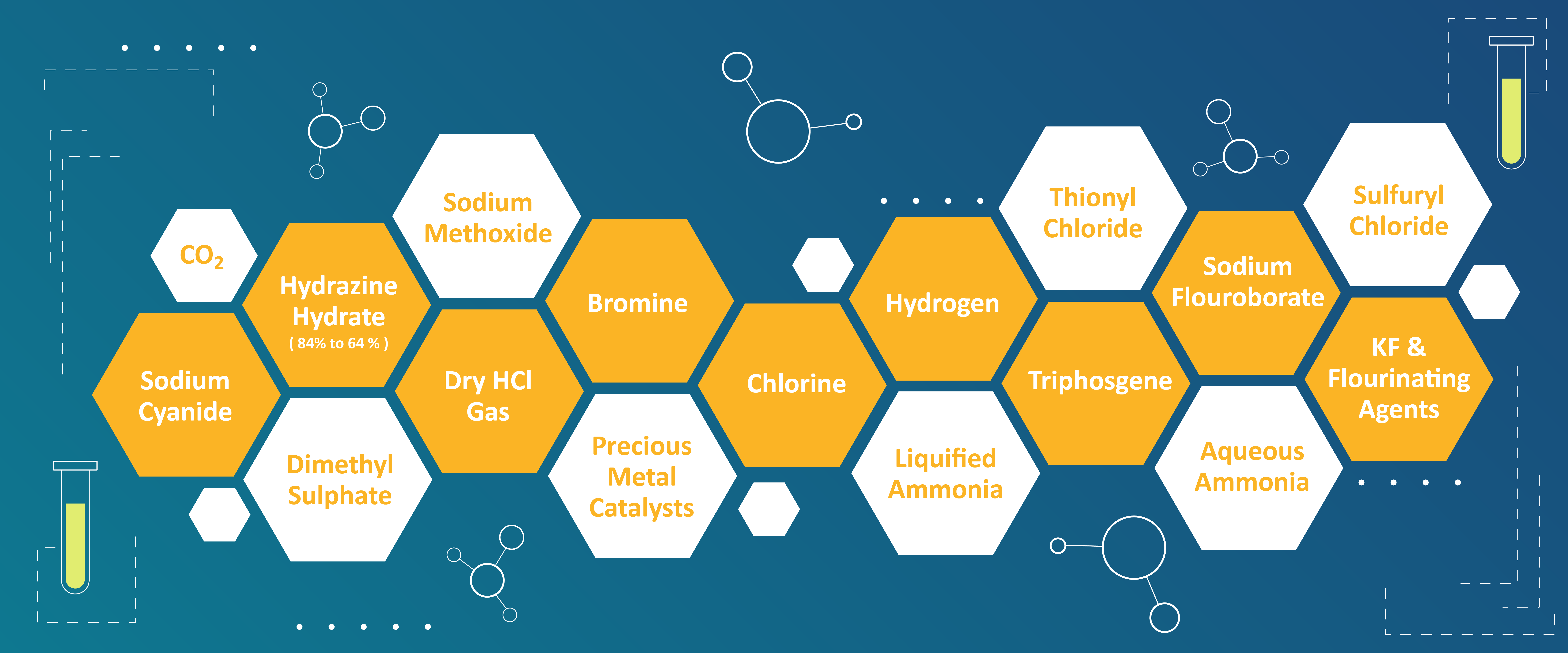

Hazardous Materials Handled

INVENTYS has developed comprehensive capabilities and infrastructure to handle a wide range of hazard chemicals at its manufacturing facilities. This has been achieved in a very structured manner over the last many years. With a deep understanding of the multi-dimensional requirements required to achieve this, we have a very well-equipped team of personnel who are very well trained in the storage and handling of these hazardous chemicals. In addition to the training, our plants are very well designed to handle these hazardous chemicals on a routine basis with specific emphasis on design and operations addressing the elements of waste disposal, exposure, emergency response and documentation. Safety is one of the core values of Inventys which is always addressed when we take up projects which involve hazardous chemicals. We continue to improve our process and work flows to ensure that we embrace the developing technologies that ensure that our facilities are a very safe place to work for our employees.

Flow Chemistry Expertise

INVENTYS has excellent flow chemistry capabilities to handle extremely exothermic reactions and involving hazardous chemicals. Backed by an excellent infrastructure and a talented team, Inventys has successfully developed, optimized processes which are now commercial manufactured in our facilities.

A multi-disciplinary team of synthetic organic chemists, process chemists, analytical chemists and chemical engineers ensure that all the elements of flow processes are well understood to address the inherent challenges associated with batch processes. This team develops the appropriate reactor systems with necessary process controls like temperature, flow rate, mixing, pressure, etc based on the specific reaction needs of a process. They are also backed by a very experienced analytical team and automation / control system engineers who utilize the laboratory data to successfully design reactor systems for scalability and reproducibility. The elements of safety, waste management are also addressed in our integrated approach for developing processes based on the principles of flow chemistry.

Green Chemistry Track Record

Innovation & Green Chemistry are core elements of the INVENTYS pathway. It starts in R&D with concepts of maximizing atom economy. The researcher’s design processes such that the final molecule contains the maximum proportion of the starting materials. They try to minimize the use of blocking or protecting groups.

Aside, the use of feedstocks from renewable sources as raw materials is an important element.

Catalysis helps us to increase energy efficiency and to avoid stoichiometric reagents. From the environmental perspective, we try to select chemical pathways that reduce intrinsic hazards and the amount of hazardous chemicals.

Also, in utilities INVENTYS is following the philosophy of minimal impact. As an example, INVENTYS is using biomass instead of using coal to generate energy and steam. The biomass is derived from the agricultural waste for feeding our boilers.

Deep Backward Integration

INVENTYS has strategically built its operational expertise to minimize its dependence on external vendors /suppliers for its raw materials. This has enables Inventys to be seen as a reliable sourcing partner by its customers globally. Our team of chemists and process technologists have a demonstrated track record of defragmenting our customers supply chain supplies. This has been achieved by developing innovative routes of synthesis and also optimizing them at our pilot plant and manufacturing facilities in a very efficient manner. These efforts translate into better supply chain stability, assured quality and provides us a very competitive advantage to serve our customers.

Process Development, Scale-up and Plant Design

Main focus of INVENTYS R&D is to develop the optimal production process for the product. This starts with lab work in gm scale including evaluating, applying route scouting and optimization in later stages of the development to end up with the most optimal manufacturing process.

The process design involves evaluating and simulating minimum amounts of the individual stages as well as selecting the most economical raw materials avoiding dependencies like single supplier. These services are the core activities of INVENTYS team of chemists and engineers to ensure best-in-class solutions

Analytical Services

INVENTYS provides access to a diverse range of analytical methods and evaluation exercises to meet the needs of specific projects. This is the prerequisite for Process Development, Design & Control as well as to guarantee quality as well as quality consistency at a later stage.

Quality Management

INVENTYS has developed a very robust Quality Management System (QMS) to accomplish its objective of achieving a high level of operational excellence at its facility. The different elements that cover the absic principles of quality management pertaining to its focus on customers, engaging its employees, developing a process based approach to issues /challenges, focusing on continuous improvement have enabled INVENTYS to earn the trust and confidence of its customers globally. The accreditation of its facilities for ISO9001, ISO 14001 and ISO45001 reflect its commitment and adherence to embrace the principles of quality management in its business operations.

Project Management

INVENTYS project teams have the experience focus to take up any information given and to give information & support to our customers which is needed in the actual phase of a project. Key element is to create the most economical and ecological production process for the product based on information provided by the customer. The key contact will stay your direct access to INVENTYS from the start of the project up to successful completion as well as in the maturity phase.

Efficient Management

(DUMMY TEXT)INVENTYS has developed a very robust Quality Management System (QMS) to accomplish its objective of achieving a high level of operational excellence at its facility. The different elements that cover the absic principles of quality management pertaining to its focus on customers, engaging its employees, developing a process based approach to issues /challenges, focusing on continuous improvement have enabled INVENTYS to earn the trust and confidence of its customers globally. The accreditation of its facilities for ISO9001, ISO 14001 and IS 45001 reflect its commitment and adherence to embrace the principles of quality management in its business operations.

Efficient Raw Material Procurement

The customers benefit from the strong backbone of INVENTYS procurement network, which ensures economical, ecological and sustainable access to the required raw materials.

Best-In-Class IPR Practices

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do

Automated Process Plants

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do